Get to know in detail the steps for creating your garments

OUR EXPERIENCE WILL MAKE THE ENTIRE PROCESS EASY

Professional consulting

PRIOR ADVICE

Before choosing the final garments you wish to customize, our expert sales team will contact you to better understand your needs, resolve any doubts, and offer you the solution that best fits your budget and specific sports modality.

Once the consultation is completed and the technical equipment to be customized is known, you will receive your tailored formal budget by email.

Unlimited design

DIFFERENTIAL CREATIVITY

Once the budget and sales conditions are accepted via email, it is time to start creating your exclusive design. From the very first moment, you will have the individualized assignment of a person from the technical and prepress team so that you have direct contact with the creative department and the design can be adjusted quickly to what you are looking for. If you are not clear about your design, our experience will allow us to create several proposals from scratch tailored to your profile.

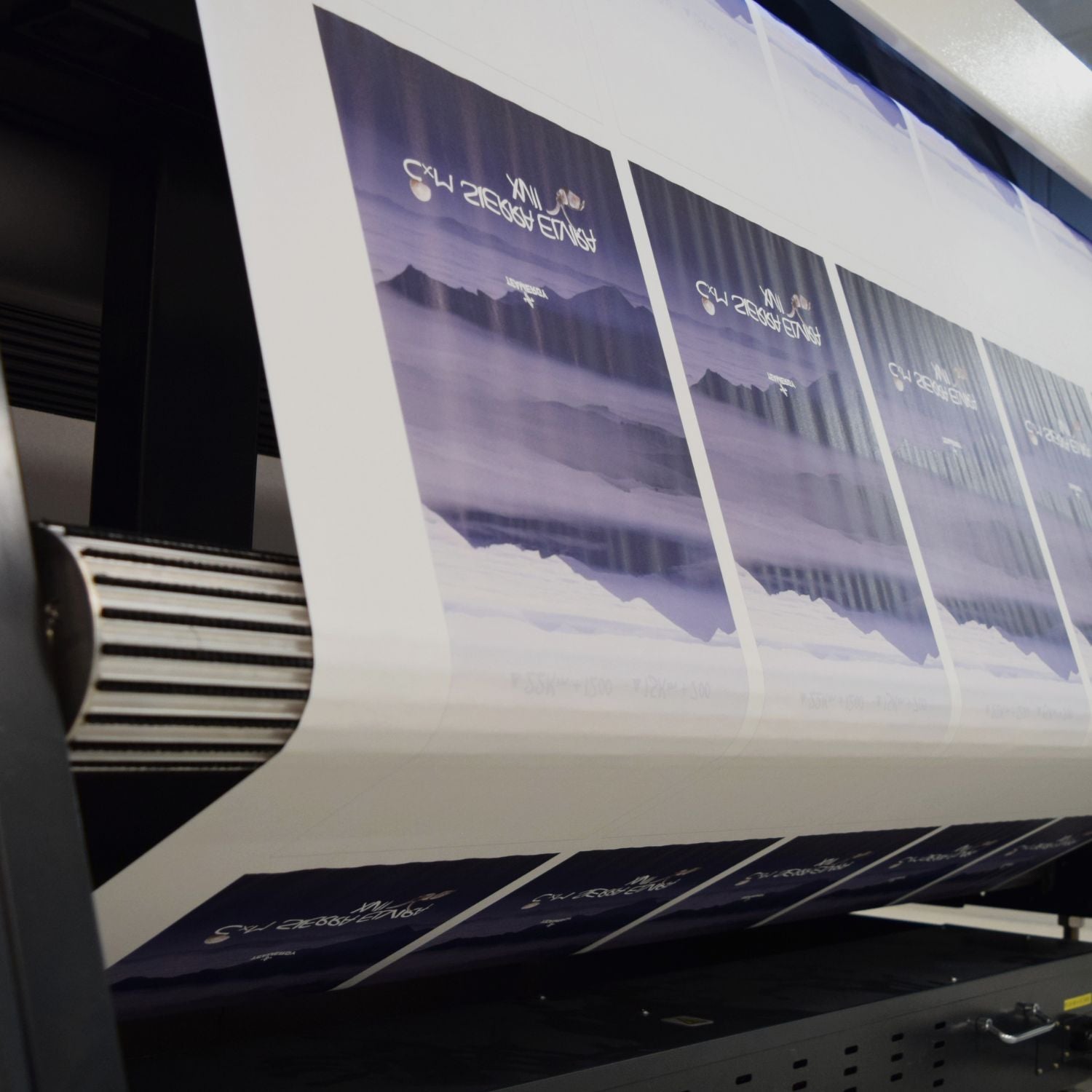

Maximum quality printing

FIRST-CLASS MACHINERY

After closing creativity our prepress team will adapt the design to all the individual pieces and patterns that make up each garment, so that they can later be printed on a special textile sublimation paper.

We have state-of-the-art printing plotters with a rip that matches colors, ensuring maximum definition and minimizing printing risk factors.

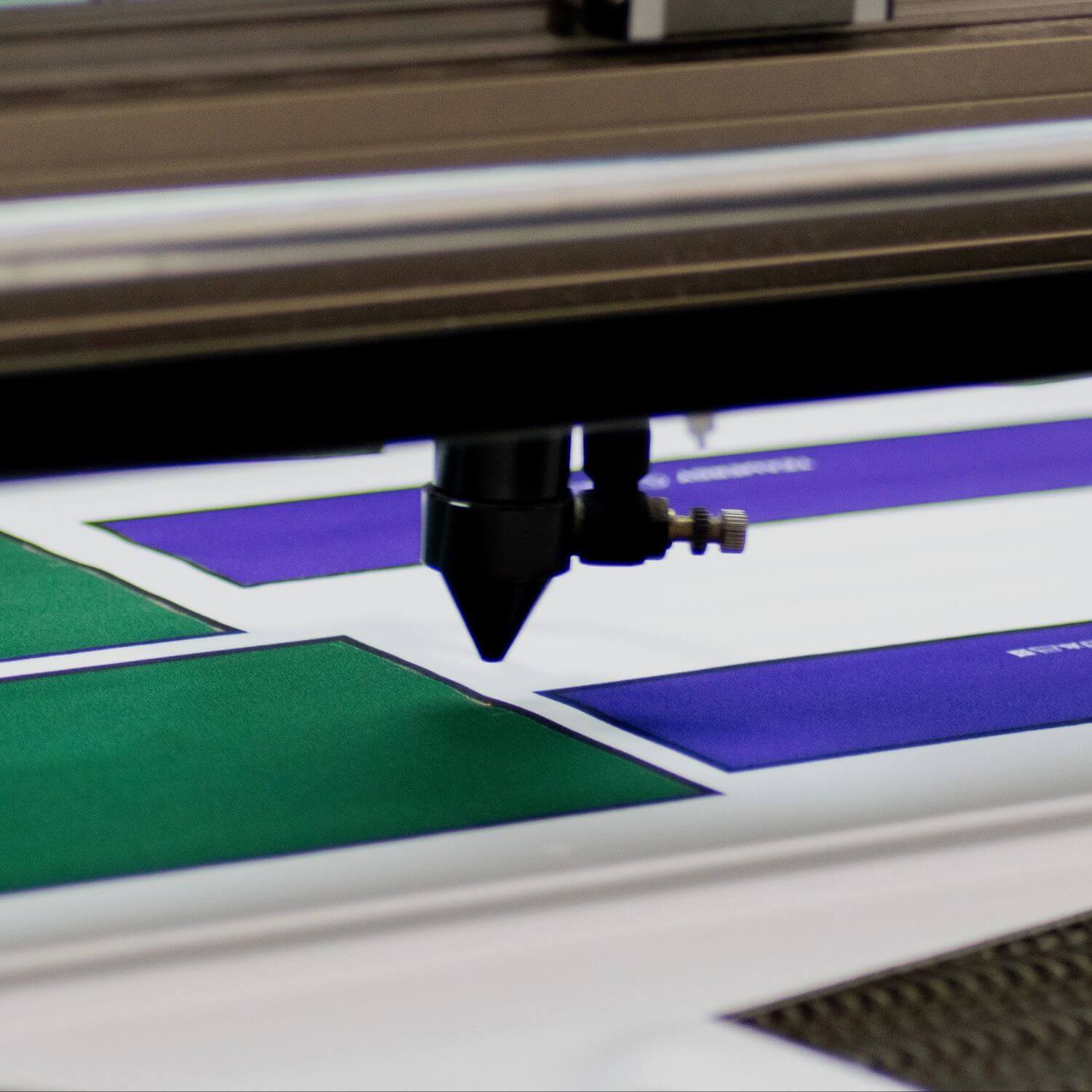

4. Industrial cut

PREMIUM TECHNICAL FABRICS

Before your design becomes part of the equipment, it is necessary to prepare and meticulously organize all the specific pieces and fabrics that compose it. In this section, we have the most cutting-edge laser cutting technology that guarantees a clean finish with maximum precision.

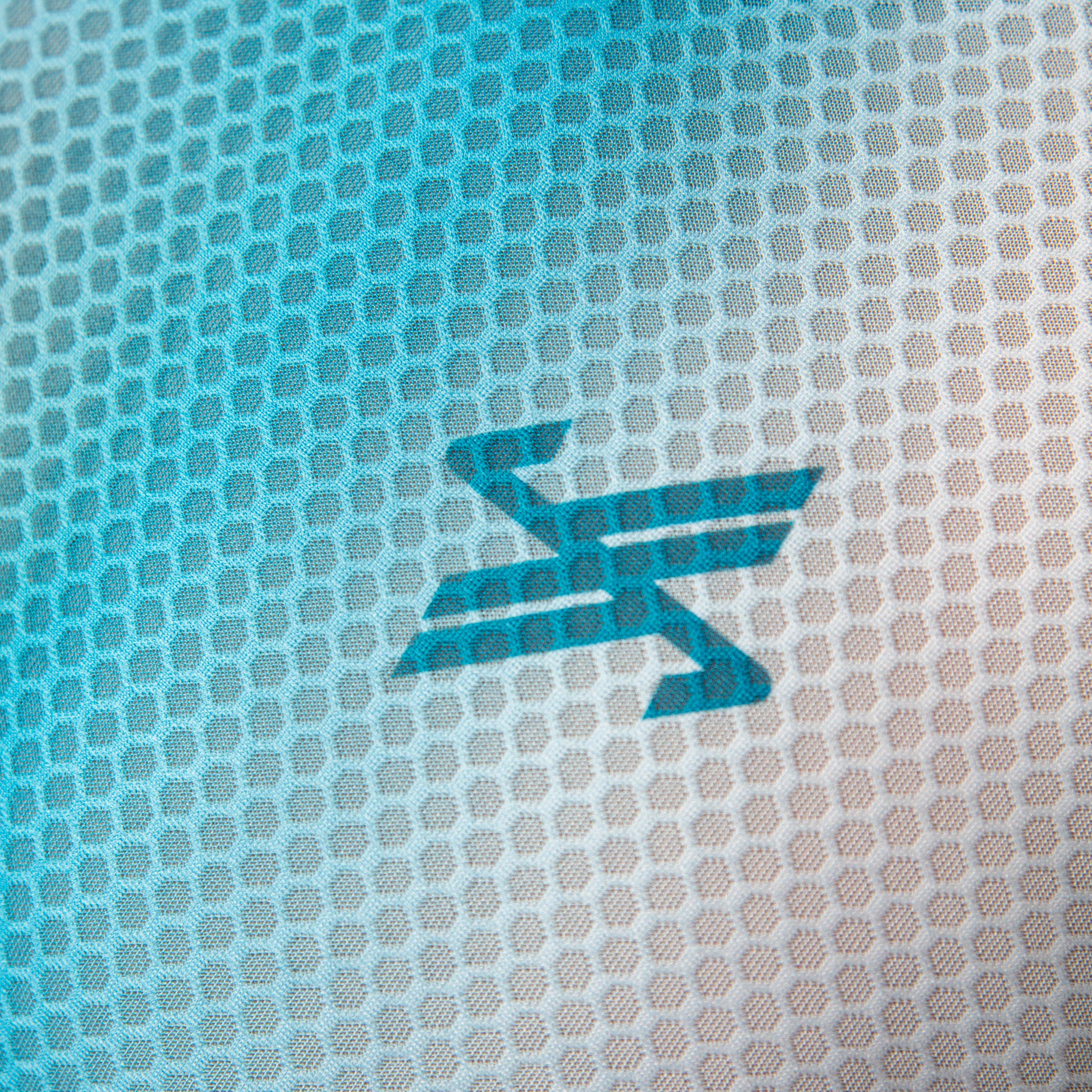

5. Stamping on the fabric

TEXTILE SUBLIMATION

Through a heat transfer, the special inks detach from the printed paper and are absorbed into the fibers of the fabric, becoming part of it.

Our top-level calenders allow for precise regulation of factors such as speed, temperature, and pressure to provide each fabric with the optimal conditions for sublimation.

Specialized tailoring

YOU TAKE MADE REALITY

Our qualified and experienced sewing team is responsible for meticulously sewing all the pieces that make up the technical garment. Depending on the piece to be sewn, we use a different type of stitching that adapts to the area and its use, to ensure maximum durability and functionality, achieving premium finishes.

Quality control

CERTIFIED TRACEABILITY

After the sewing phase, the quality team thoroughly reviews each garment individually to ensure it meets our quality standards.

Throughout the production chain, we have strategically placed control points to ensure the identification of non-compliant products.

In addition, before manufacturing we carry out an internal color sample on selected fabric and a physical validation sample to ensure compliance with the club or sports event.

Packaging

OPTIMIZED PACKAGING

We deliver all the sports equipment ironed, folded, and bagged in a transparent bag or in a recycled cardboard wrap.

In addition, the packaging of each order is presented separated by model, pattern, and size, to facilitate subsequent handling.

Our garments are freshly finished in our factory and ready to be delivered.

SPECIFIC PATTERNS

Adapted to each sport and differentiated by male, female, and children.

ORDERS FROM 10 UNITS.

Minimum amounts accessible to any type of club or event.

Replacement

Sublimation allows for a 100% guaranteed replenishment without stock breakage.

AFTER-SALES SERVICE

We efficiently resolve any questions after the delivery of your order or incident.

full print customization

textile sublimation advantages